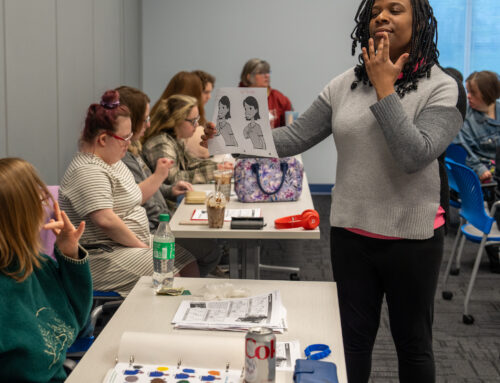

Reopening ADEC’s day centers, summer camp and transportation over the past few weeks came with many logistical changes. Beyond the visible shifts for social distancing and other novel coronavirus prevention measures, reopening ADEC Industries saw a change in the name of sustainability with the competitive integrated employment shop’s continuation – but only that portion.

The manufacturing lines continue to hum. Visiting the facility last week, an order of 22,200 silver linings trash bags placed on June 4th was receiving the finishing touches to be shipped. Small assembly orders for Elkhart firms Lithotone, ASA Electronics and Dometic were in progress. Nothing much has changed – on the surface. Digging deeper, the employees are receiving a more complete understanding of what it means to serve in the workforce than ever before.

“For the first couple of weeks, like anything we had that’s new, it’s been a learning curve,” said ADEC Industries manager Bob Reynolds. “A lot of the workers have been going through the process of learning how to be assimilated into a normal working environment. Punching in. Punching out. A group leader used to do that for them. For the most part, they’re understanding what the expectations of a work environment are. If they were to leave here and go into other community employment, they are prepared for the expectations.”

The focus of the solely competitive integrated employment edition of ADEC Industries replicates a standard employment situation. Elkhart County boasts a manufacturing-heavy economy and what better way for clients to potentially immerse themselves in it (or any other line of work) than within the familiar settings of ADEC. The men and women running the bag line and other stations at ADEC Industries are treated as employees like their peers around town. They are perhaps even better off than their peers for receiving a market rate wage, averaging the amount paid to their local colleagues, instead of merely minimum wage.

“They’re getting cross-trained on learning new skills,” Reynolds said of the advantages to the smaller employee roll. “They’re getting cross-trained in a team environment. Even though we have social distancing and are spaced apart, they’re working as a team to get that job accomplished because it has to ship by a certain date. They are going to understand the team concept from a production standpoint and from the expectation of a boss because we’re in this together.”

Things certainly appeared fine when visiting last week. Socially distant mask-wearing ADEC Industries employees diligently went about their tasks on the floor. The space, dubbed “the shop,” saw trash bags being cut by humming machinery, small parts being sorted at side tables, and cardboard being assembled then filled with the finished products. The shop is more efficient and streamlined than before.

“We put an emphasis on businesses where we can be as sustainable organizationally as we can be,” Reynolds said, not sounding dissimilar from a foreman for any number of local factories. “We’re constantly busy. I’ve been pleased with the cooperation. I’ve been pleased with the backup help that I’ve had transitioning, keeping people going and stepping in when needed.”

So long as the shop has orders to fill, that progress will only keep getting better as the clients turned employees settle into their roles.